Products.

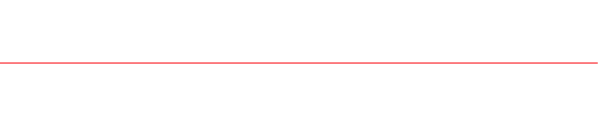

PE film

EDSFlexibles coats, laminates

and metallises PE film when the product requires advanced performance. Polyethylene's good conformability and seal-ability are inherent characteristics, making the film a viable option for use with other materials to create unique characteristics.

PA/BOPA film

Polyamide (PA) is widely used for the production of flexible packaging film, in most cases combined with polyolefins as a component of a multilayer structure. It has found numerous applications for its unique combination of properties like mechanical strength, transparency, thermoformability and barrier.

Polyamides may be processed into film by blown or cast film process, oriented or non-oriented. Standard extrusion equipment may be used, however post-treatment by humidification helps to postcrystallize PA film and achieve dimensionally stable, ready-to-use film of high quality.

Combined PA/PE film is providing high transparency, fast sealing, and extreme puncture resistance via premium quality raw materials.

EDS Flexibles offers a broad range of biaxially oriented nylon films. Our process results in a product having superior mechanical properties, such as puncture-, impact-, burst- and tear-resistance.

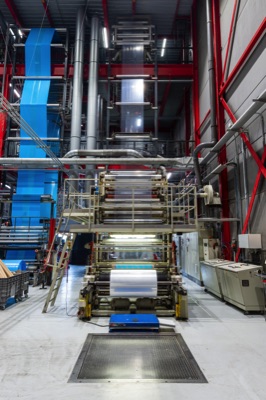

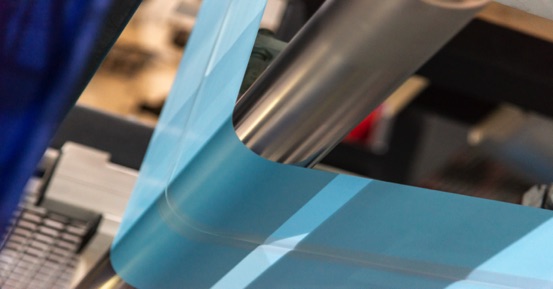

CPP film

Cast Polypropyleen (CPP) foil is manufactured by extrusion - forcing out the still liquid plastic mass from the head onto the rotating cylinder with a smooth surface.

This main cylinder as well as several following ones is being intensively cooled, which results in rapid hardening of the plastic mass. This process allows to obtain films with mechanical properties similar to PE.

CPP film features high transparency and gloss. It characterized low specific weight (0,90 g/cm3) causes the yield to be greater than in other films of the same thickness, high flexibility and also high resistance to tearing and puncture (easy to perforate).

PET film

Polyester or Polyethylene Terephthalate (PET) is a high-performance, crystal clear thermoplastic. In comparison with other common plastic films, PET film has excellent dimensional stability, low moisture absorption, and good retention of physical properties over a fairly wide temperature range. It also has superior UV resistance, excellent electrical properties, good optical clarity, high gloss, gas barrier up to 21 days but only moderate moisture barrier properties.

It is the ideal film for quality printing and lamination and a good choice for a high performance plastic films and sheets.

PET is fully recyclable and can be easily reprocessed into many other products for many different applications. However, biodegradable additives are available that enhance the biodegradation of this plastic without affecting the physical properties.

Due to the low odor, high chemical resistance and inertness, many PET grades are suitable for packaging applications under FDA regulations.

ALOX coated films

Aluminium Oxide (Alox) coated Polyester film is providing an exceptional barrier for a long shelf life of your products. At the same time it gives you the opportunity to include a window in your packaging and improve your product presentation. For securing the high quality and protecting the barrier properties of this film our Alox films are top coated.

Alox coating is the application of a thin and highly transparent coating of aluminium oxide on packaging films that gives the materials extremely high moisture and gas barrier properties that rival those of aluminium foils and metalised films. It is the only truly high-barrier flexible packaging material available that is transparent and allows the packaged product to be clearly visible.

The levels of barriers available from Alox coated films are superior to those provided by other transparent flexible packaging materials like PVDC-based structures and EVOH coextrusions.

Furthermore, moisture and gas permeabilities are not affected by high levels of temperature or relative humidity and are independent of the base film thickness thus enabling maximum downgauging of packaging materials.

An important feature of Alox coated films is that they are microwavable. As they can be retorted as well, this makes them ideally suited for the packaging of processed foods that can be microwave heated or cooked in the pack itself before consumption.

Alox coating is a cutting edge technology processed by only a handful of film manufacturers. EDS is working together with highly specialised partners owning the Alox coating capabilities.

BOPP film

Biaxially Oriented Polypropylene film (BOPP) presents both side heat sealable layers, transparent, general purpose.

BOPP film features good heat sealability, high transparency and gloss, beneficial mechanical properties and low water vapor and odor-values. Slip and anti-block properties facilitate its processing on automatic packaging machines.

One side corona treated is offered as the standard film version. Heat sealable outer layers allow sealing at temperatures lower than the polypropylene melting point.

EVOH film

Ethylene-vinyl alcohol copolymer (EVOH) is a flexible, crystal clear, and glossy thermoplastic copolymer with excellent flex-crack resistance, and very high resistance to hydrocarbons, oils and organic solvents. It also has some of the best barrier properties to gases such as oxygen, nitrogen, and carbon dioxide making it especially suited for packaging of food.

In comparison with many other common films, EVOH film has superior barrier properties. However, EVOH loses its good gas barrier properties when exposed to moisture. For this reason and to optimize both cost and performance, it is frequently used in multilayer, co-extruded films like HDPE, PP, and PET, which have superior moisture barrier properties.

Due to the low odor, high chemical resistance, and inertness, many EVOH grades are suitable for packaging applications under FDA regulations.

EVOH is extensively used for atmosphere packaging where a certain atmosphere is needed inside the package to improve the shelf life of food products, therefore this film is used for fresh products when minimal permeability is needed.

And a selection of sealing temperatures depends on the characteristic of heat sealing bars and sealing speed.

CPP foil is suitable for lamination with other materials and metallization. It also has very good sealability on “hot wire” or “hot knife” appliance and gives very strong sealing by hot jaws due to the inner laminate layer.

A metalised CPP foil has an even higher gloss, greater transparency and better heat resistance.

CHOOSE YOUR LANGUAGE

HOME | PRODUCTS | SERVICES | SUSTAINABILITY | OUR CLIENTS | CONTACT US

quality ı flexibility ı reliability